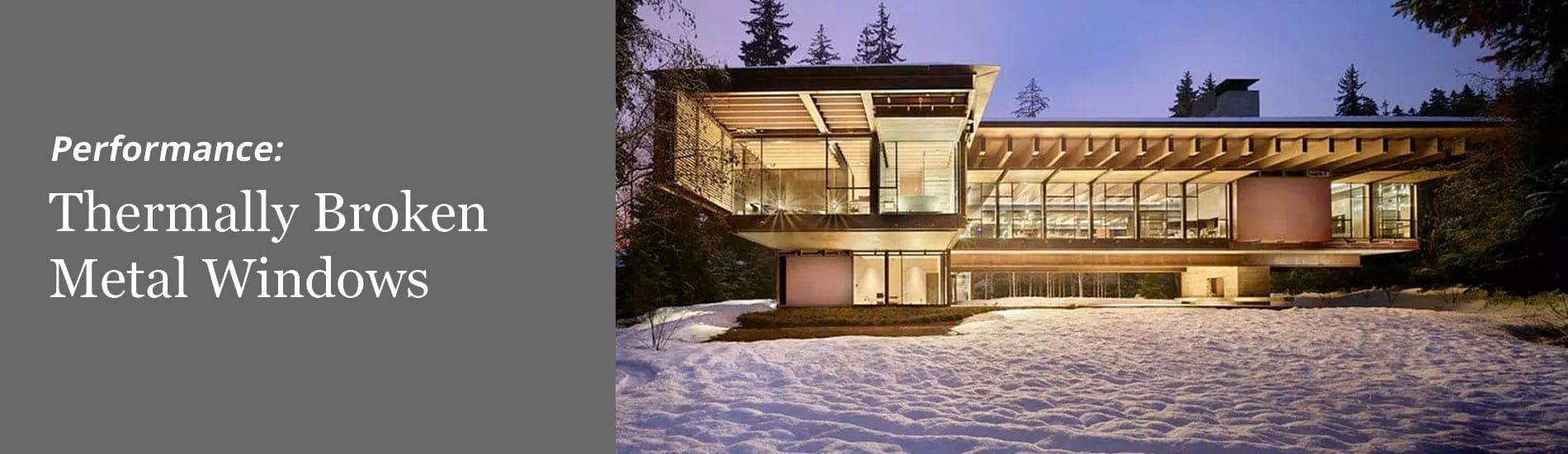

Benefits of Thermally Broken Metal Windows

The “Metal Movement” and “Thermally Broken.”. Why you want your metal windows to be BROKEN.

Thermally broken metal windows provide several benefits over non-thermally broken systems. We are often asked about specific performance benefits.

The basic performance premise is:

- Improved overall thermal performance over traditional non-thermally broken systems.

- Improved NFRC U-Values over non-thermally broken systems. The lower the u-value, the better the performance.

- Improved NFRC Condensation resistance factors (interior sweating/ice build-up).

- Narrow profiles equal or similar to traditional non-thermally broken.

- Easier Code Compliance than non-thermally broken systems.

Sounds like a no-brainer, right? So how does it work?

What “Thermally Broken” Means

First of all – what does “thermally broken” mean? While the name itself has a negative connotation to it, the concept is very positive when it comes to metal windows and doors.

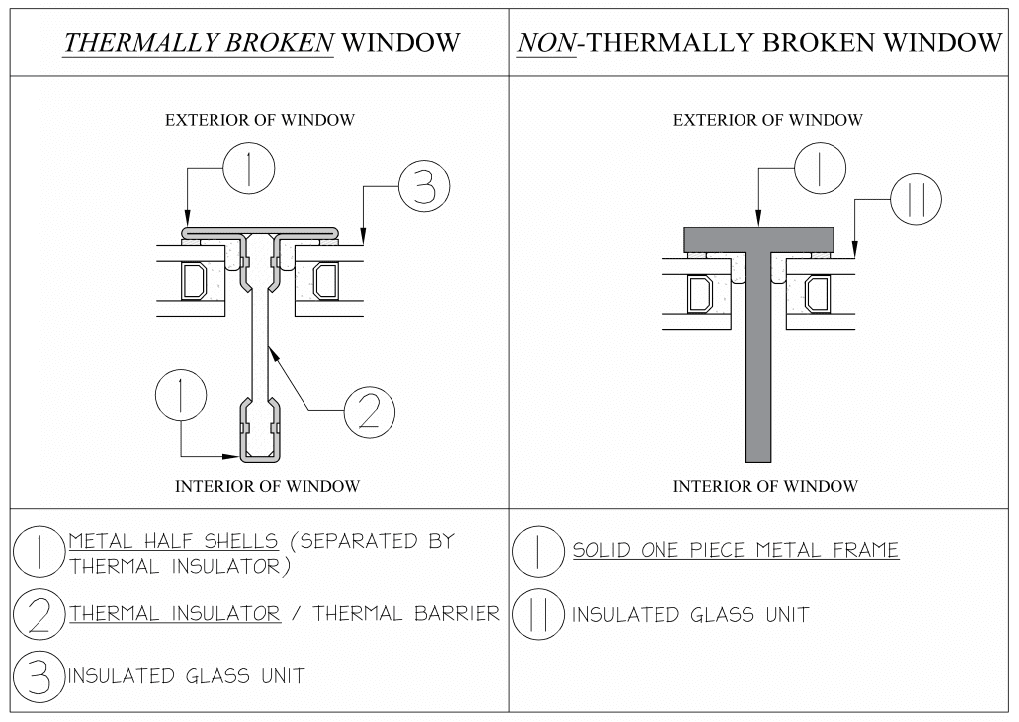

In layperson’s terms, thermally broken refers to high-performance insulator material separating two metal halves, whether aluminum, steel, or bronze. The insulator cuts down the ‘thermal bridging.’ With NON thermally-broken systems, or solid metal systems, cold and heat can exit or enter the interior of the home by travelling or “bridging” through the solid metal perimeter frame or true divided muntins.

Thermally broken refers to high-performance insulator material separating two metal halves — aluminum, steel or bronze.

Introduce the ‘broken’ aspect via thermal insulator, and the insulator acts as a defensive line against thermal transfer.

Whether heat or cold, thermal transfer (or lack of it) does affect the comfort level inside the home. We invest in heating and air-conditioning in order to be comfortable. It’s no different with your thermally broken windows. It is literally a “Quality of Life” component.

For those who prefer visuals, here’s a quick example:

Key Points to Note with Thermally Broken Windows

When considering or specifying metal windows and doors for your new luxury home, getaway property, or boutique commercial project, there are a few key points to manage when discussing thermally broken versus solid metal profiles:

- Is the project in an area of higher heat, humidity or temperatures like Austin, Arizona, or Los Angeles?

Metal sweats — not like 45 minutes on the spin bike, but it sweats. When the hot steel contacts the cooler inside temperatures of a structure, the metal has the potential to sweat condensation. Thermally broken will mitigate the potential for sweating as the interior side of the steel is separated from the hotter exterior surfaces with the insulator. - Is the project in an area of colder characteristics such as Aspen, Jackson Hole or Connecticut? During the colder months the goal is to keep the chill out and the warmth in without working your heating system to death. Solid metal profiles allow direct cold transfer from the exterior to the interior. This cold transfer when meeting the interior heat can cause moisture and condensation on the glass, moisture that can form into frost buildup. Snow and frost are beautiful things- when they’re outside the home. Products that are NFRC rated have a condensation resistance rating. The higher the condensation rating, the better the resistance will be to potential frosting, condensation, and sweating.

- Does your project require more stringent code compliance such as we’re seeing in areas like Seattle, Lake Tahoe, Aspen or Vancouver? Hitting the required u-values and SHGC co-efficient is becoming difficult with traditional non-thermally broken unless you’re willing to entertain multiple pieces of glazing and glass so dark it would make your Ray- Bans jealous. Code compliance can typically be achieved with thermally broken products by incorporating dual glazing and the right combination of performance LoE coatings.

A typical thermally broken steel casement window, with dual glazing a single coat of performance LoE, can have a u-value of 0.34 and a condensation resistance factor of 58. A typical non-thermally broken steel window can have a u-value of 0.46 and condensation resistance of 25. The lower the u-value number, the better the thermal performance of the window, and the higher the condensation rating value, the better the resistance to potential condensation. These values will change depending on the inclusion of TDL or SDL muntins or if higher performing glass is requested.

To achieve thermally efficient metal windows, having a true thermal break is the essential starting point. This needs to be combined with the appropriate glazing specifications to meet the specific code values or preferred performance levels for each project. Glass and glazing is a world unto itself so have a conversation with your window fabricator about the code compliance, aesthetics and costs of the various options.

Metal windows have been around for centuries in some of the world’s most iconic structures, sought after for their narrow profiles, longevity, structural strength and low maintenance. Innovations in thermal break technology have added thermal performance to this list and the process continues unabated.

So now you know why you want your metal windows to be “broken”.

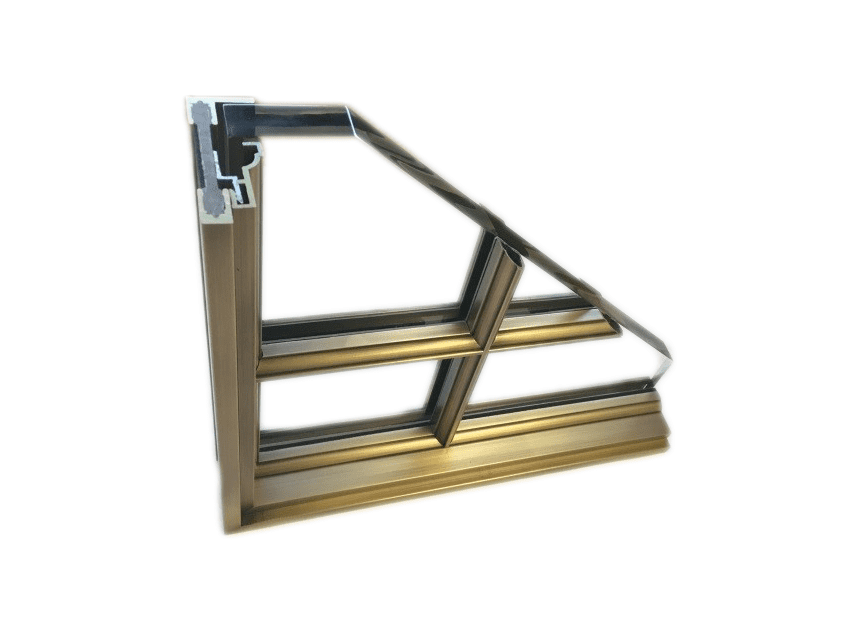

Section of a Thermally Broken Bronze Window